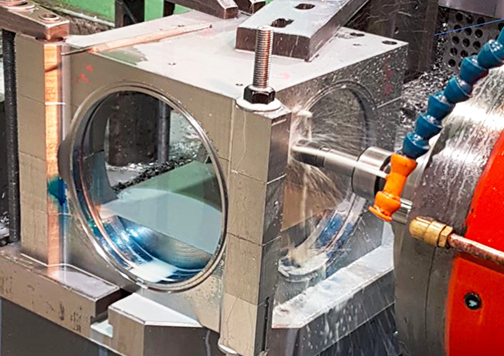

machining

Facility

Under one roof, you will find world class machinists, industrial mechanics, welders and steel fabricators, all ready to give your project the integrated attention it deserves, utilizing both CNC and conventional machining.

Our 25,000 square foot facility allows us to handle projects up to 17 tons and 10 feet in diameter.

Equipment / Capabilities

CFM owns and operates a wide variety of equipment, including large horizontal and vertical boring mills, multiple lathes up to 30 feet, mill machines, CNC, drill presses and portable equipment.

We work with a wide variety of materials including mild steels, regular carbon steels, titanium, stainless, brass, aluminum, and plastics.

Learn more about our equipment capabilities.

Large Machine Shop Equipment

Kuraki Horizontal Boring Mill

|

Stanco Vertical Boring and Turning Mill 2

|

Geminis Lathe

|

CTX Gamma 3000TC

|

Ecomill 1100V

|